Traction machine brake

2021-05-17

The elevator adopts a machine-electric friction type normally closed brake. The so-called normally closed brake refers to the brake braking when the machine is not working, and the brake is released when the machine is running. When the elevator brakes, the brake force is generated by the friction between the brake belt and the brake wheel by the action of the mechanical force; when the elevator is running, the brake is released by the electromagnetic force, so it is also called the electromagnetic brake. According to the coil operating current generated by the brake electromagnetic force, it is divided into an AC electromagnetic brake and a DC electromagnetic brake. Because the DC electromagnetic brake has stable braking, small volume and reliable operation, the elevator uses DC electromagnetic brakes. Therefore, the full name of this brake is a normally closed DC electromagnetic brake.

The brake is the basic device to ensure the safe operation of the elevator. The requirements for the elevator brake are: it can generate enough braking torque, and the braking torque should be independent of the steering of the traction machine; the shaft and the reduction gear of the traction motor during braking The worm shaft should not generate additional load; when the brake is released or braked, the requirement is smooth, and it can meet the requirements of frequent starting and braking; the brake should have sufficient rigidity and strength; the brake has high resistance. Grindability and heat resistance; simple structure, compact, easy to adjust; should have artificial release device; low noise.

Basic requirements for brake function:

1 When the elevator power supply loses power or the control circuit power supply loses power, the brake can brake immediately.

2 When the car is loaded with 125% of rated load and is running at rated speed, the brake should stop the traction machine.

3 When the elevator is in normal operation, the brake should be kept in the state of continuous energization; after the brake release circuit is disconnected, the elevator should be effectively braked without additional delay.

4 Cut off the brake current, using at least two separate electrical devices. When the elevator stops, if the main contact of one of the contactors is not open, the elevator should be prevented from running again at the latest when the next direction of operation changes.

5 The elevator traction machine equipped with a manual handwheel should be able to release the brake by hand and require a sustained force to keep it released.

Brake construction and how it works

The working principle of the brake: When the elevator is at rest, no current flows through the coils of the traction motor and the electromagnetic brake. At this time, because there is no attraction between the cores of the electromagnets, the brake pads will be under the pressure of the brake springs. The brake wheel is tightly held to ensure that the motor does not rotate; when the traction motor is energized and rotated, the coil in the brake electromagnet is simultaneously energized, and the electromagnet core is rapidly magnetized to attract the brake arm to cause the brake spring to be subjected to the brake spring. The force, the brake pad is opened, completely separated from the brake wheel, the elevator can be operated; when the elevator car reaches the required stop, the traction motor loses power, and the coil in the brake electromagnet also loses power at the same time. The magnetic force in the electromagnet core disappears rapidly, and the iron core is reset by the brake arm under the action of the brake spring, so that the brake pad holds the brake wheel again and the elevator stops working.

Permanent magnet synchronous elevator gearless traction machine

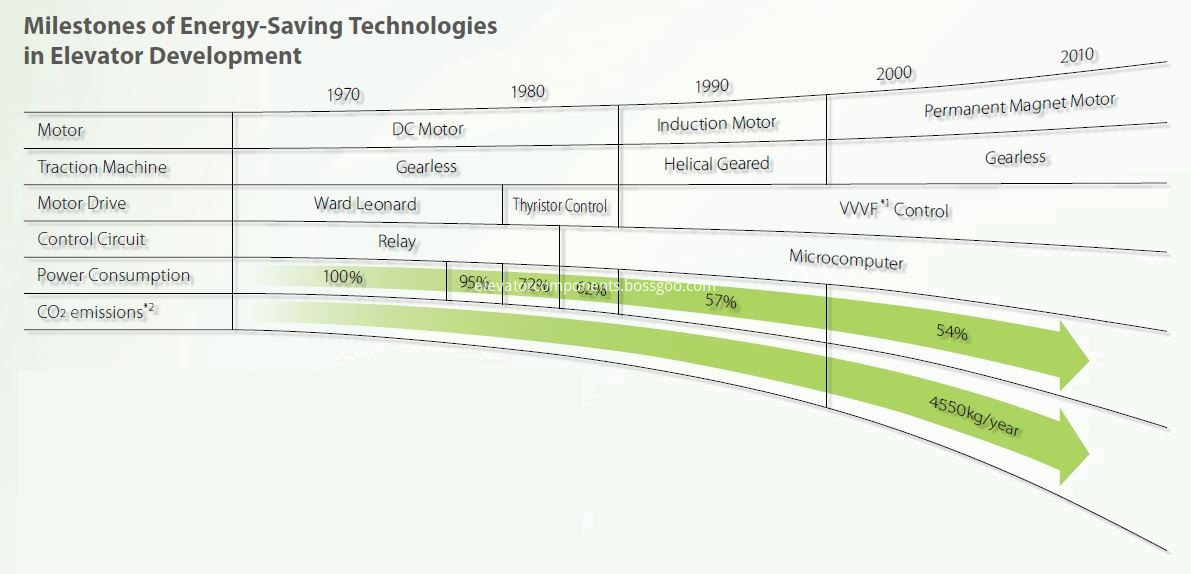

VVVF asynchronous elevator geared traction machine gearbox worm gear

AC380V/50Hz Elevator Traction Machine, AC220V/60Hz Elevator Traction Machine,

Roping 1:1 2:1 4:1

Elevator Traction Machine Kits & Packages

Items Included Recommendations: Traction Machine, Encoder, protective cover, handwheel, machine bed, diverting pulley, damping pad as one package

OTIS Elevator TRACTION MACHINE KITS & PACKAGES, Thyssen Elevator TRACTION MACHINE KITS & PACKAGES, KONE Elevator TRACTION MACHINE KITS & PACKAGES, GiantKONE Elevator TRACTION MACHINE KITS & PACKAGES, ThyssenKrupp Elevator TRACTION MACHINE KITS & PACKAGES, Schindler Elevator TRACTION MACHINE KITS & PACKAGES, XJ Schindler Elevator TRACTION MACHINE KITS & PACKAGES, Xizi OTIS Elevator TRACTION MACHINE KITS & PACKAGES, Mitsubishi Elevator TRACTION MACHINE KITS & PACKAGES, Shanghai Mitsubishi Elevator TRACTION MACHINE KITS & PACKAGES, Fujitec Elevator TRACTION MACHINE KITS & PACKAGES, Hitachi Elevator TRACTION MACHINE KITS & PACKAGES, Toshiba Elevator TRACTION MACHINE KITS & PACKAGES, Hyundai Elevator TRACTION MACHINE KITS & PACKAGES, LG Elevator TRACTION MACHINE KITS & PACKAGES, Sigma Elevator TRACTION MACHINE KITS & PACKAGES, Express Elevator TRACTION MACHINE KITS & PACKAGES, GUANGRI Elevator TRACTION MACHINE KITS & PACKAGES, FUJI Elevator TRACTION MACHINE KITS & PACKAGES, BLT Elevator TRACTION MACHINE KITS & PACKAGES, CANNY Elevator TRACTION MACHINE KITS & PACKAGES, SJEC Elevator TRACTION MACHINE KITS & PACKAGES, KOYO Elevator TRACTION MACHINE KITS & PACKAGES, IFE Elevator TRACTION MACHINE KITS & PACKAGES

Elevator Traction Machine, Elevator Geared Machine, Elevator Gearless Machine, Geared Traction Machine, Gearless Traction Machine

Wantong Hydraulic Co.Ltd. http://www.zjelevatorcontrolsystem.com